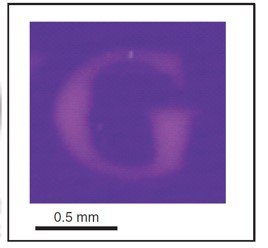

The industrial manufacturing of electronic and optoelectronic devices involves selective masking and etching methods to create nano- and micro- scale patterns on substrates. These methods include the highly developed photolithography and electron-beam lithography, allowing the fabrication of high-resolution features down to sub-100 nm. However, lots of sophisticated processing steps must be accurately carried out to realize the desired patterns. During the last few years, extensive research activities have been focused on developing alternative approaches for patterning structures at low-cost and on large areas. As a result, several less-sophisticated and non-photolithographic techniques have been developed. Inkjet printing and 3D printing are among those techniques that have attracted much attention and have been used for fabrication of various devices such as solar cells, thin film transistors, displays, radio frequency identification tags, and organic devices. They have also been utilized to form patterns of proteins and cells that can be used for biological applications. In our group, we have devoted part of our research activities to the formulation of nanoinks used for inkjet printing applications. Parameters such as particle size, surface charges, rheological properties, and ink stability have been studied. We have also combined soft lithography with inkjet printing aiming to enhance the resolution of the printed features down to 250 nm. The interaction between the ink droplets and substrates is very crucial on achieving high resolution, smooth, and thickness controlled printed structures. Devices such as antennas and gas sensors have been printed and optimized. Recently, an advanced 3D printer has been installed and will be used for the fabrication of microfluidic devices, sensors, and spacers for membrane modules.